Membrane structure has been widely used in various fields, and it has appeared more and more frequently. People's understanding of membrane structure also has a certain basis. Today we come to learn and understand the method of cutting the membrane structure.

1. Introduction to cropping methods

There is an error in the process of cutting and splicing the membrane structure. This is because firstly, there must be an error when the planar surface is used to form a space curved surface. Secondly, the membrane cloth is an anisotropic non-linear material. When the shape of the space with various curvatures changes, it will inevitably be different from the original design shape. To date, a number of approaches have been established to address this issue. It is difficult to evaluate which method has a high accuracy, but there are still several criteria that can be used to judge whether these cropping methods are practical. That's reliability, flexibility, and completion time.

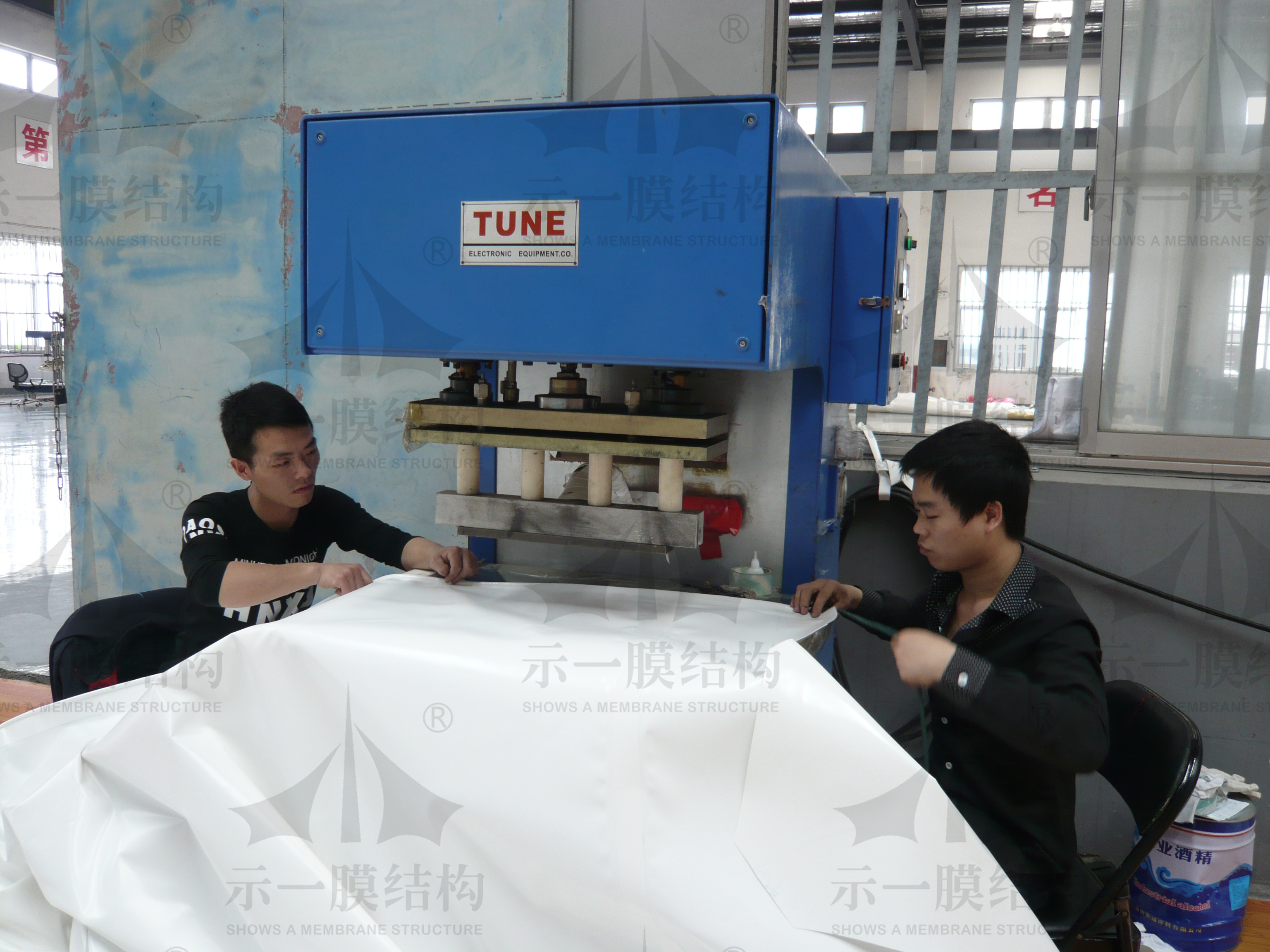

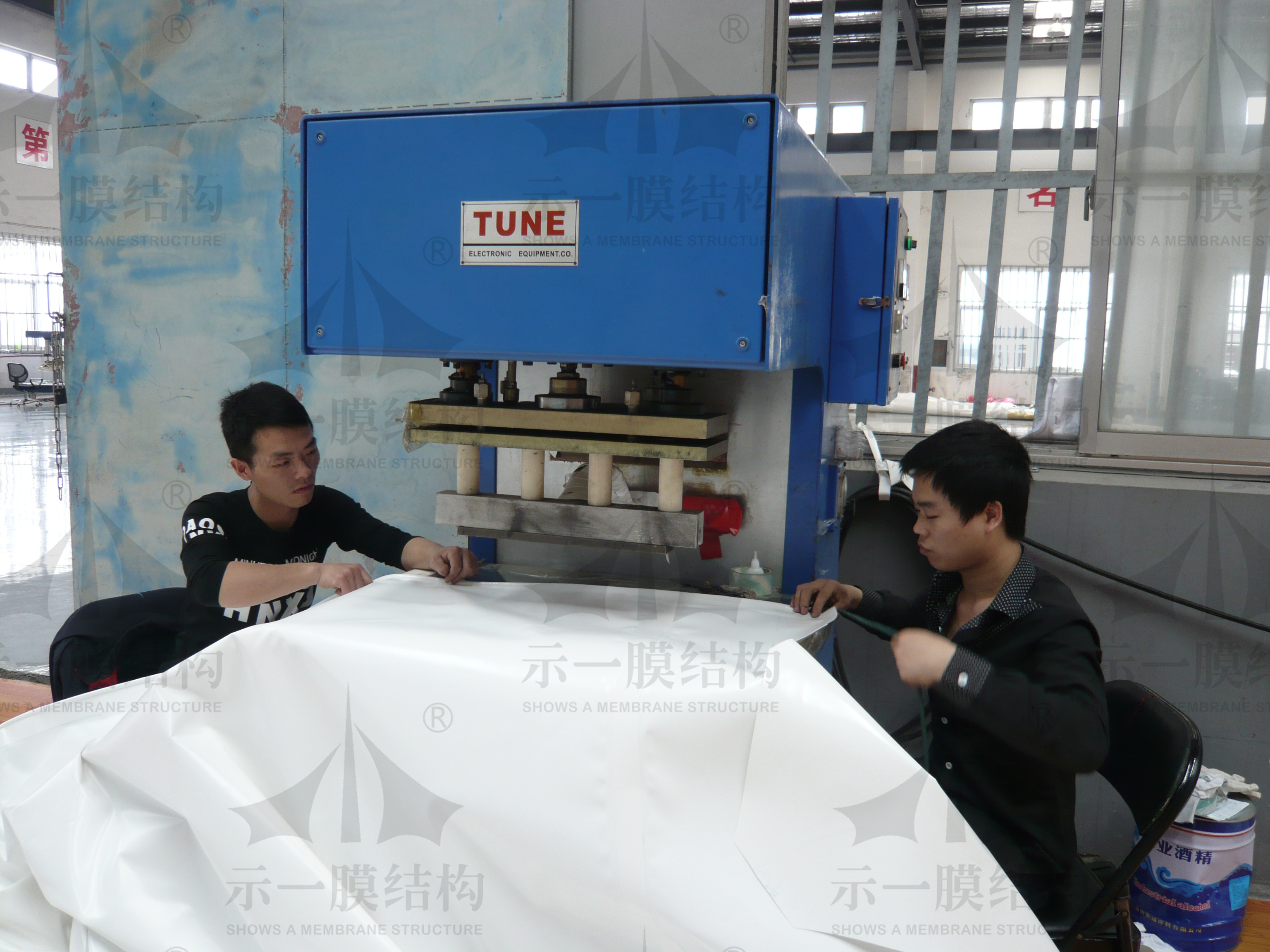

2. Membrane structure interactive cutting process

Arrangement of tailoring seams

There are several factors to consider when arranging the slits on the surface of the membrane structure:

1) Surface curvature

None of the previous cropping methods gave curvature at any point on the surface. And because this software uses a curved membrane unit, the curvature of each unit can be obtained. If the curvature of adjacent elements is very different, it means that the surface is very distorted at this position. If the cutting seam is restarted without cutting off, the boundary of the cutting film block will have a large arc here. From the change trend of the curvature of adjacent units, the approximate trend of the geodesic can be determined.

2) the width of the film material

When the plane mesh is divided during the form-finding analysis, the width of the film material must be considered. Try to make the membrane unit contained in a membrane cloth as complete as possible, otherwise the position of the boundary point of the membrane block must be determined by interpolation calculation.

3) The direction of the border

If the boundary is relatively straight, consider using the long side of a membrane block as the boundary. Otherwise, only the short sides of multiple membrane blocks can be used to join this border.

4) beautiful

Because the film material is light-transmissive, the weld seam can be clearly seen in the actual structure, so the layout of the cutting seam must be regular and reasonable, and it is best to form some beautiful patterns to increase the aesthetics of the structure. If a pressure or spinal cord is provided on the surface of the film, it is better to make the cutting seam coincide with the pressure or spinal cord so that the cord does not disturb the pattern arrangement of the weld.

Original finishing from Shanghai Shows A Membrane Structure Co., Ltd.

Reprint please specify