Business phone:

021-33860589

021-33860893

24-hour service hotline:

18621082988

Business email:

shows123@163.com

Company website:

www.shows-a.com

National Service Hotline:

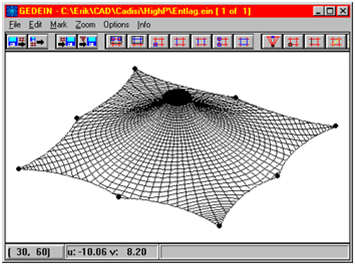

Membrane structure design:The design of the membrane structure mainly includes four major issues: shape design, initial equilibrium shape analysis, load analysis, and cutting analysis.

According to the customer's needs, first find the shape to determine the initial equilibrium surface of the membrane structure under the given boundary and pre-tension conditions, and design a solution.

According to the customer's needs, first find the shape to determine the initial equilibrium surface of the membrane structure under the given boundary and pre-tension conditions, and design a solution.

The factors to be considered include: 1) boundary conditions; 2) reasonable pre-tension values; 3) architectural modeling; 4) use functions.

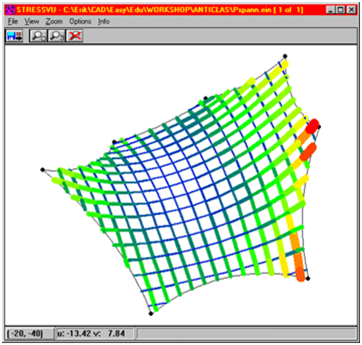

The purpose is to check whether the stiffness of the structure is sufficient and the stress is within the allowable range under the action of various load combinations. Ensure that the membrane (or cable) will not be loosened due to excessive deformation or damaged due to excessive stress.

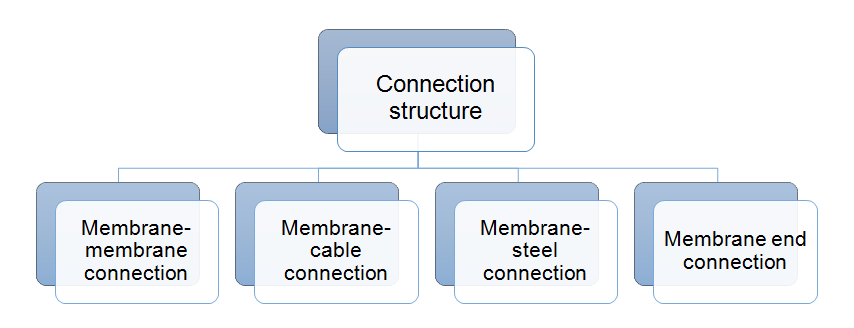

The visual form of nodes and connections is related to people's perception of indoor and outdoor space and the expression of social and cultural values. Structural logic and art are equally important in connection and node design. It can be seen that the design of nodes and connections is one of the keys to the overall structural design. The treatment of connections and nodes also reflects the designer's understanding of structural logic and material properties.

The visual form of nodes and connections is related to people's perception of indoor and outdoor space and the expression of social and cultural values. Structural logic and art are equally important in connection and node design. It can be seen that the design of nodes and connections is one of the keys to the overall structural design. The treatment of connections and nodes also reflects the designer's understanding of structural logic and material properties.

The visual form of nodes and connections is related to people's perception of indoor and outdoor space and the expression of social and cultural values. Structural logic and art are equally important in connection and node design. It can be seen that the design of nodes and connections is one of the keys to the overall structural design. The treatment of connections and nodes also reflects the designer's understanding of structural logic and material properties.

Architectural Design Concept

Membrane structure differs from the traditional structure in the design process, it breaks the traditional "architectural first, structure later" design process. Membrane architectural design is considered during the initial conception stage by integrating the architectural plan with the structural plan. The architectural plan is also the initial conception of the structural plan, so that the three aspects of structure, function, and aesthetics can be organically combined in the design and the structure can be fully utilized. The characteristics of form.

The membrane structure is not only light-transmitting, light weight, fast construction speed, unique shape, but also its light and high-strength characteristics make it an unsurprising building, with outstanding safety, and because the engineering membrane is difficult to burn and self-cleaning. It has good durability and easy maintenance.

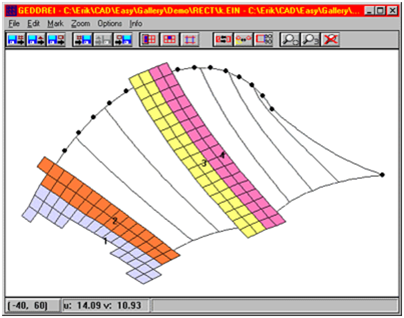

The cutting analysis is performed on the structural surface that meets the design requirements obtained through the morphological analysis, and the structure of the morphological analysis and the cutting analysis is the basis of the load analysis (the main axis direction of the film should be considered during the load analysis). The accuracy directly affects the degree of approximation of the actual surface after stitching and the theoretical surface obtained from the morphological analysis and the accuracy of the load analysis.

The cutting analysis is performed on the structural surface that meets the design requirements obtained through the morphological analysis, and the structure of the morphological analysis and the cutting analysis is the basis of the load analysis (the main axis direction of the film should be considered during the load analysis). The accuracy directly affects the degree of approximation of the actual surface after stitching and the theoretical surface obtained from the morphological analysis and the accuracy of the load analysis.

The determination of the cutting line is affected by various factors, such as the effect of the layout of the cutting line on the aesthetics of the entire film structure; the width of the cut strips after expansion cannot be greater than the width of the film material to improve the utilization of the film material.

The determination of the cutting line is affected by various factors, such as the effect of the layout of the cutting line on the aesthetics of the entire film structure; the width of the cut strips after expansion cannot be greater than the width of the film material to improve the utilization of the film material.

With the ability to simulate the real wind environment, it can be simulated and simulated according to the actual wind environment;

With the ability to simulate the real wind environment, it can be simulated and simulated according to the actual wind environment;

According to the built environment and climatic conditions, a prototype-scale calculation model can be constructed, which avoids the disadvantage that wind tunnel tests can only be performed at scale.