Business phone:

021-33860589

021-33860893

24-hour service hotline:

18621082988

Business email:

shows123@163.com

Company website:

www.shows-a.com

National Service Hotline:

1. The professional and technical personnel have a trapezoidal distribution of intermediate and junior professional titles;

2. Established a professional design service company-Yuanqi Design, which is engaged in the main creative design and external source design tasks of our project. The design team personnel are responsible for the special work such as the plan drawing, construction drawing, cut-out drawing, calculation of the calculation of the design task of the enterprise, and after review and review, the multi-party control is effective;

3. Research and innovation of product development and manufacturing, construction technology, management and training of design talents, leading the technological development of enterprises.

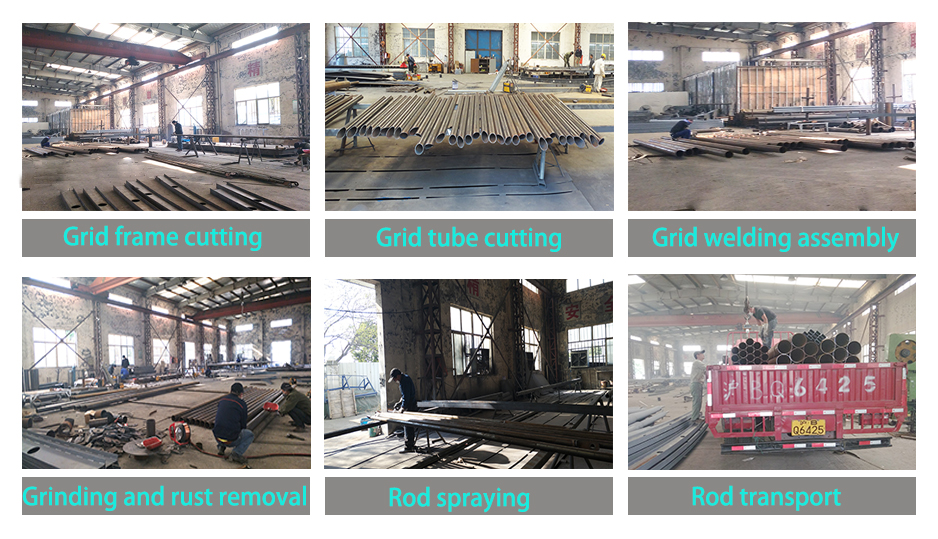

4. Steel structure area of 2000 square meters, large-scale aerial crane, CNC plasma cutting bed, punch, gas shielded welding machine, drilling machine, polishing machine and other professional equipment; professional welders, painters, riveters, all holding certificates.

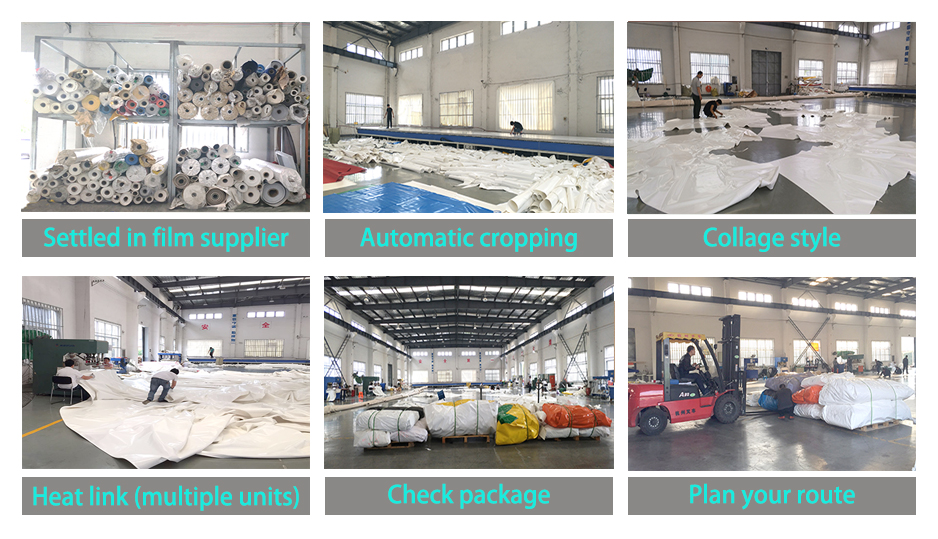

5. Membrane workshop area of 3500 square meters, with automatic cutting machine, multiple large-scale high-frequency film structure heat-sealing equipment, PTFE high-frequency special heat-sealing equipment, PVC portable welding machines and other professional processing and manufacturing equipment; the daily processing capacity of the film material is more than 1,000 square meters A number of imported and domestic brands have settled in, and various types of film materials have diversified supplies, and the price advantage is obvious. Professional master and deputy operators control the quality, and the quality assurance staff carefully checks and packs out of the warehouse.

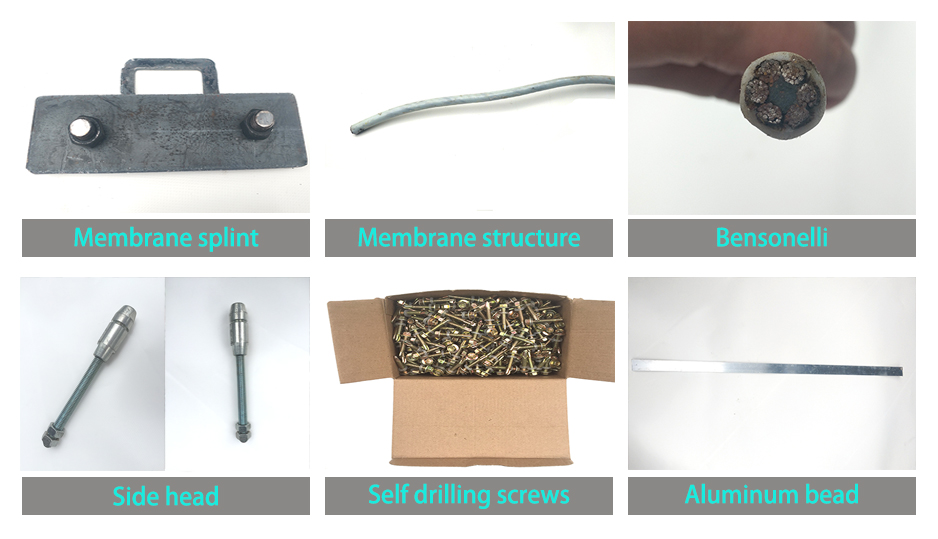

6.Persist in purchasing from the list of qualified suppliers and implement dynamic management of registered suppliers. Structural steel, standard parts, and welding materials must undergo batch-by-batch material analysis and surface hardness inspection. Arrange warehouse warehouses for warehouse registration and warehouse records to ensure the safety of raw materials.