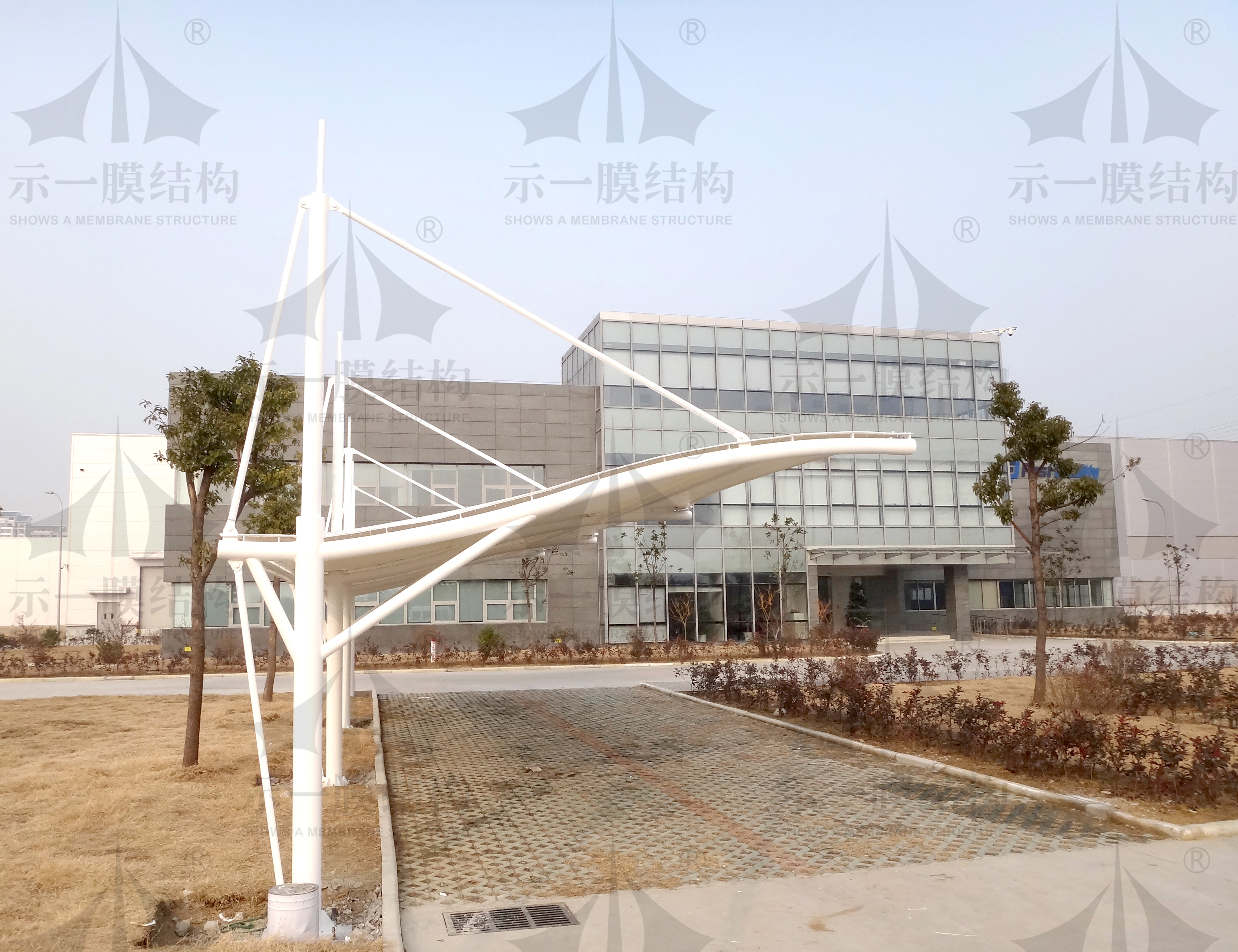

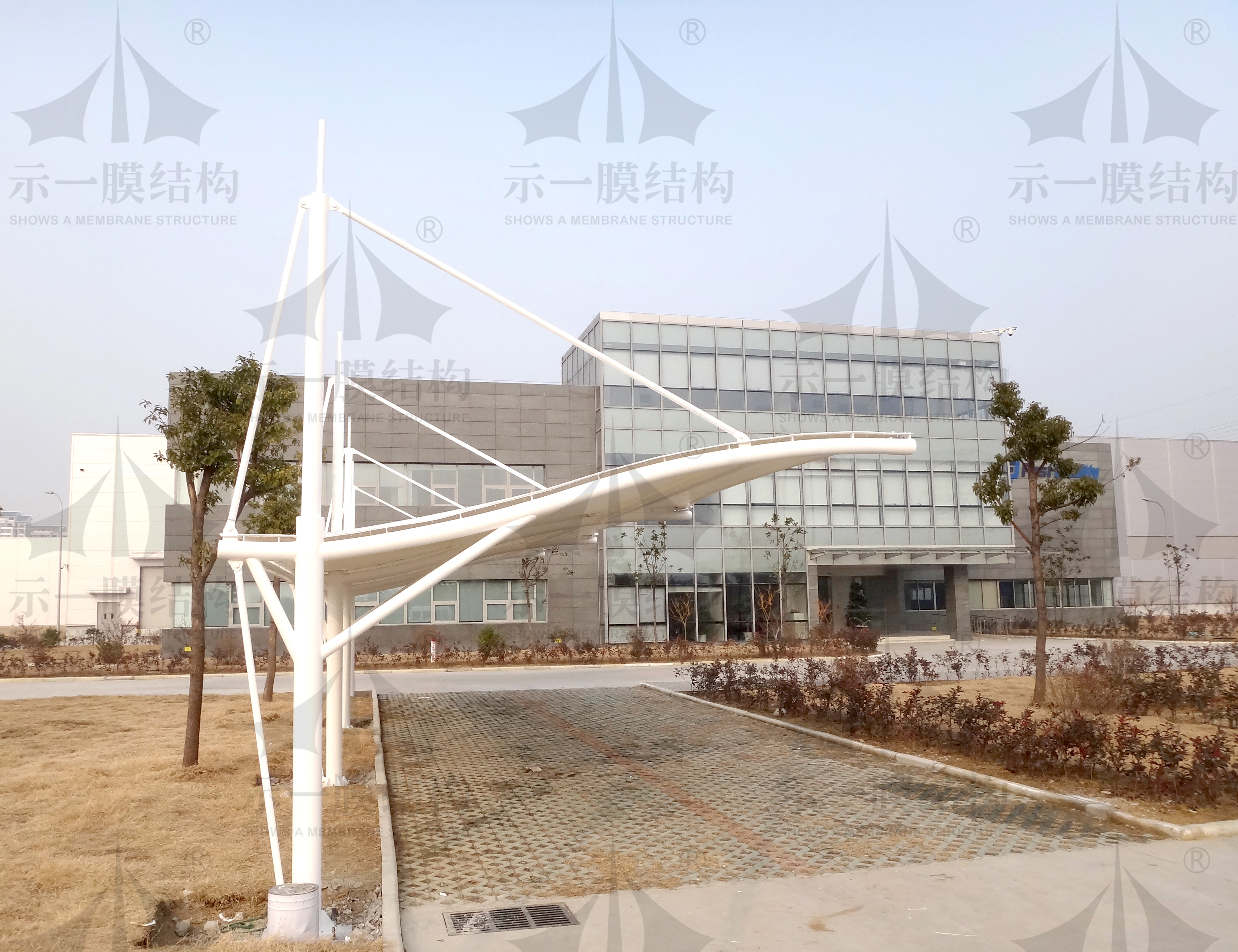

There are different types of membrane structure carports around us. The construction of a membrane structure carport requires many processes. Among them, the cutting plan of membrane structure carport membrane material needs to be paid attention to. Today we will explain in detail.

The content and process of film layout cutting planning are as follows:

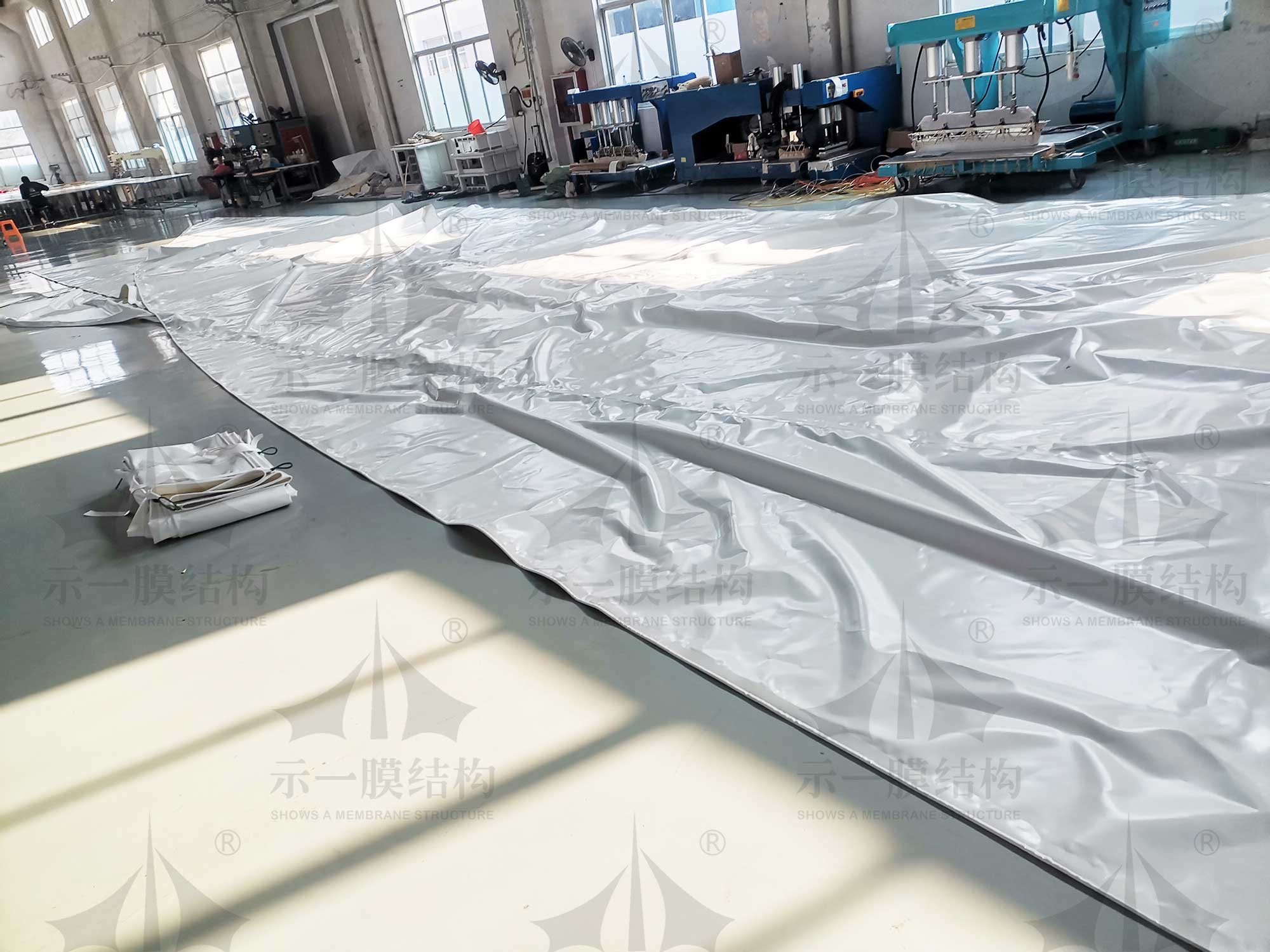

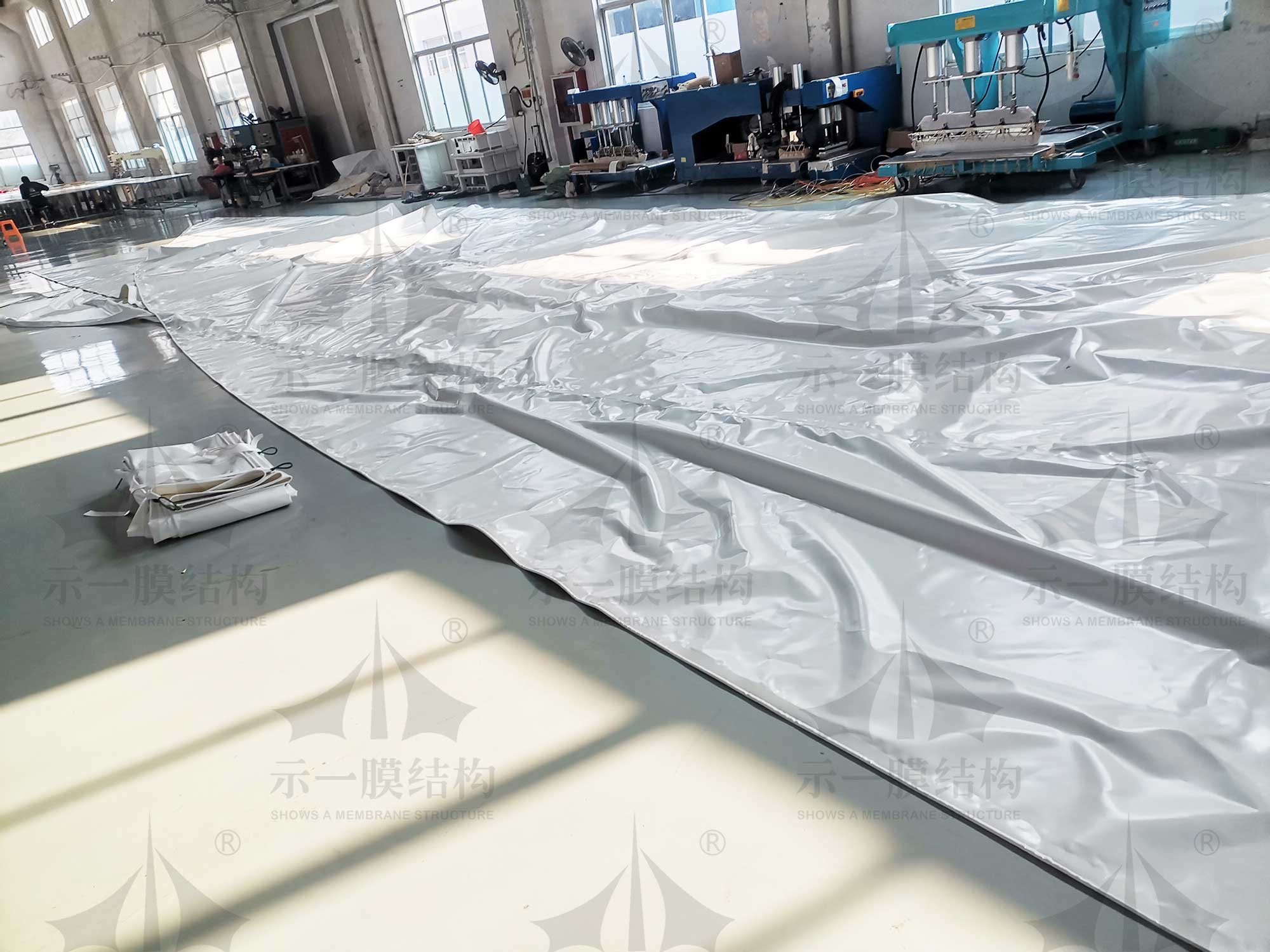

(1) Arrange cutting lines on the space film surface obtained by form-finding, and divide the space film surface into several space film strips;

(2) Open the space membrane strip as a flat membrane;

(3) Release the prestress and perform strain compensation on the flat diaphragm (that is, consider the elastic retraction of the membrane after the release of the prestress);

(4) According to the above results, plus the membrane structure at the joints and corners of the membrane, the plane cutting sheet and the membrane structure carport are obtained; the blanking drawing of the membrane material and the processing drawing of the membrane surface, the cable membrane are given. structure.

The cutting line refers to the connecting line between the film strip and the film strip on the curved surface of the space film, that is, the seam when the cutting piece is spliced with the cutting piece. The placement of cutting lines should follow these guidelines:

(1) Beautiful, with outstanding visual effect;

(2) The force bearing function is excellent, and the cutting line is generally placed in the same direction as the meridian of the membrane material, along the main stress direction of the membrane surface;

(3) It is easy to process and prevent the cutting lines from being too concentrated, so as to facilitate the disposal of corners;

(4) Saving, that is, saving the membrane material and making the total length of the seam as short as possible.

The strain compensation value (pre-shrinkage) of the film material is affected by many factors, such as the biaxial stretching function of the film material itself, the creep function, the stress level of the film surface, the shape of the cutting piece and the warp and weft direction of the material, layout standards and Supporting method, shortening of the film surface during heat sealing, ease of tensioning during molding, etc. Strain compensation is often implemented in the form of compensation rates. Strictly speaking, the strain compensation rate needs to be summed up based on the biaxial tensile test results of the membrane material under a specific stress and a stress level, in conjunction with the above factors.

The original text is from Shanghai Shows Membrane Structure Co., Ltd.

Reprint please indicate