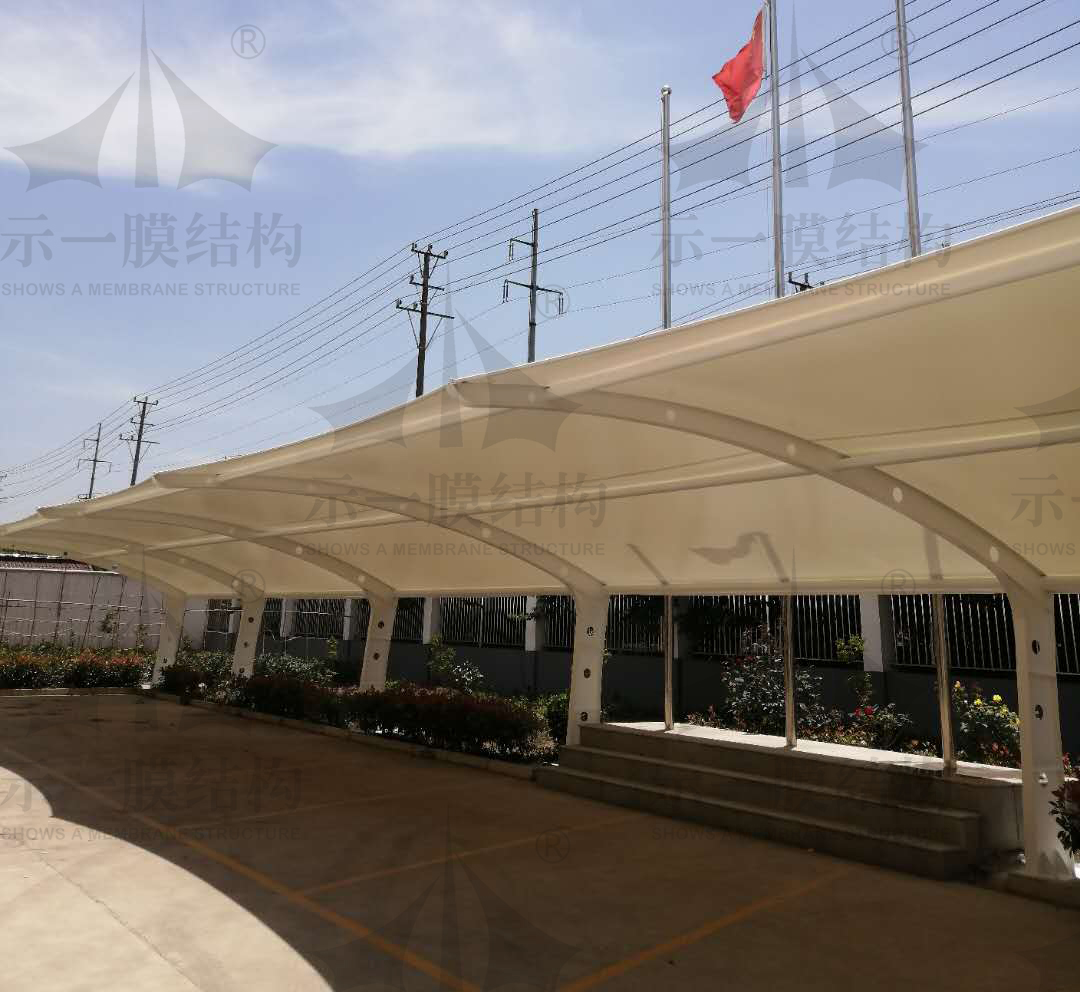

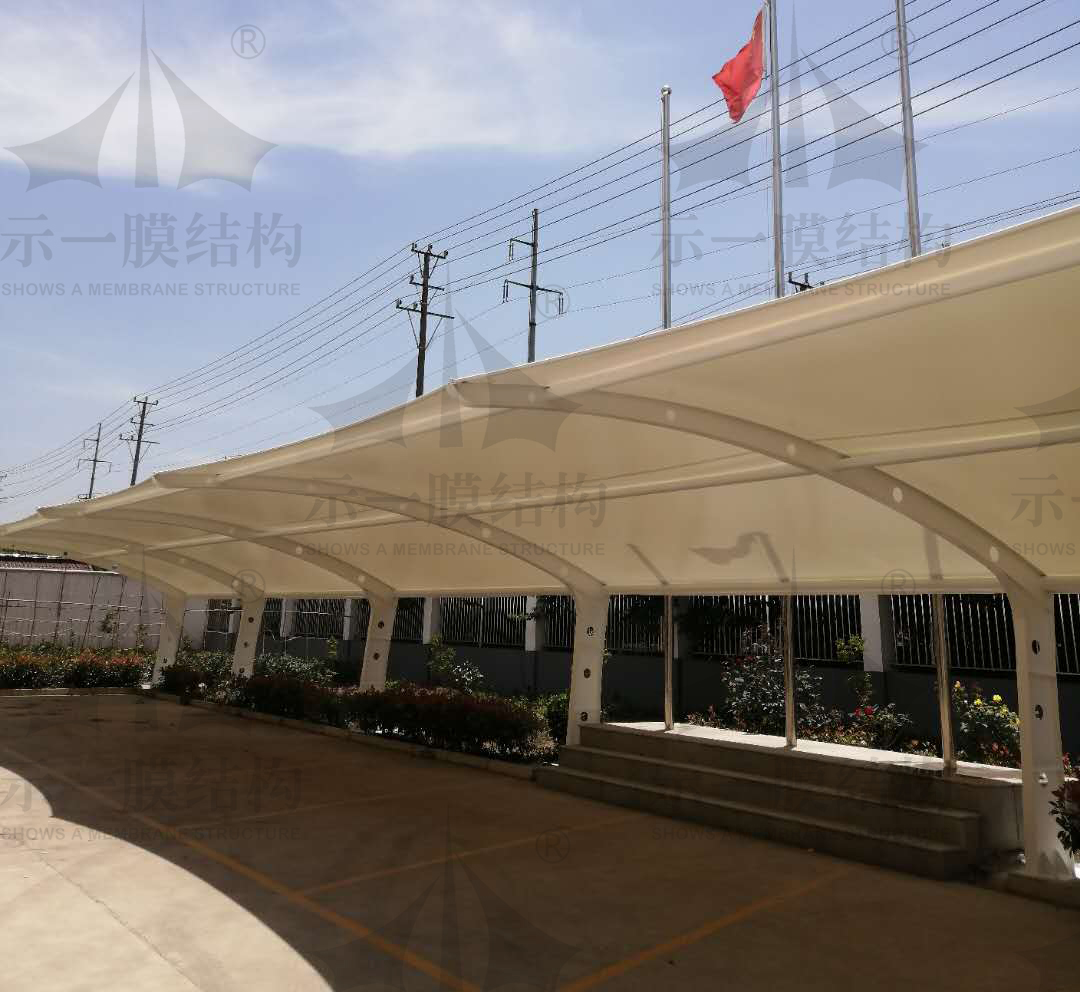

The emergence of membrane structure parking sheds not only solves the difficult problem of parking sheds. Membrane structure carport no matter in spring, summer, autumn or winter, wind and rain play a certain protective role for us. I believe that friends with cars will definitely appreciate it. This is one of the reasons why we like it.

Today’s topic is around the membrane structure parking shed, so let’s first learn and understand the necessity of quality inspection of the membrane structure parking shed. The construction inspection of membrane structure parking shed can be divided into 7 processes:

1. Connecting parts should have sufficient rigidity, strength and durability, and should not be damaged before the connected membranes, cables or steel components, and should not undergo deformation that affects the structure's force function.

2. The node structure should conform to the calculation assumptions. Consideration should be given to the influence of node structure misalignment on the cable and membrane material, the method of applying pretension, the allowable deviation of the structural device, and the possibility of secondary tensioning.

3. A high degree of water tightness should be maintained at the junction of the membrane material, and certain structural measures should be adopted to prevent the membrane material from wearing and tearing.

4. The joints should transmit force firmly and reduce the stress concentration at the joints.

5. There should be no sharp corners, burrs, or sharp points at the junction of the supporting member and the membrane material.

6. Reliable anti-corrosion methods should be used for metal connectors.

7. Ensure that the connection is safe, beautiful and reasonable.

I believe that the above 7 points can be achieved. Basically, the quality of the membrane structure parking shed will not be too problematic, and it can be used with confidence.

The original text is compiled from Shanghai Shows A Membrane Structure Co., Ltd.

Please specify