The first issue of the membrane structure editor introduced the advantages of ETFE membrane material. I believe that everyone knows the membrane material in the membrane structure. So today I will introduce a little more professional knowledge, the basic bonding method of the membrane structure.

The first type, sewing bonding:

This is the strongest method of bonding, but sewing threads are easily damaged. Sewing adhesive is usually applied to PVC coated polyester filament fabric at the same time as heat sealing adhesive, in order to obtain greater strength. If it is used outdoors, the sewing adhesive must be protected with PVC cover. Sewing bonding is not suitable for PTFE-coated fiberglass fabrics, and all other brittle fabric-based materials.

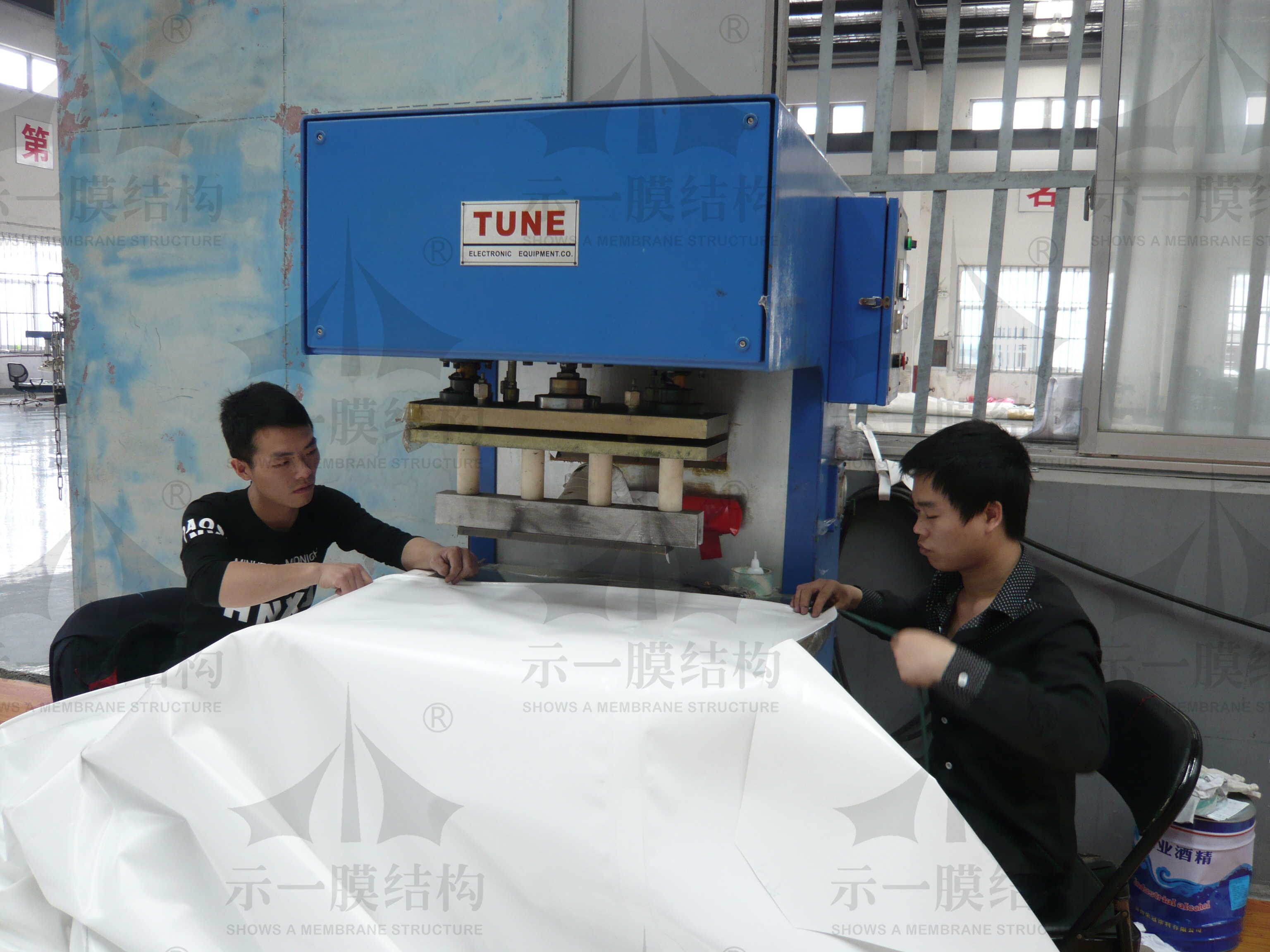

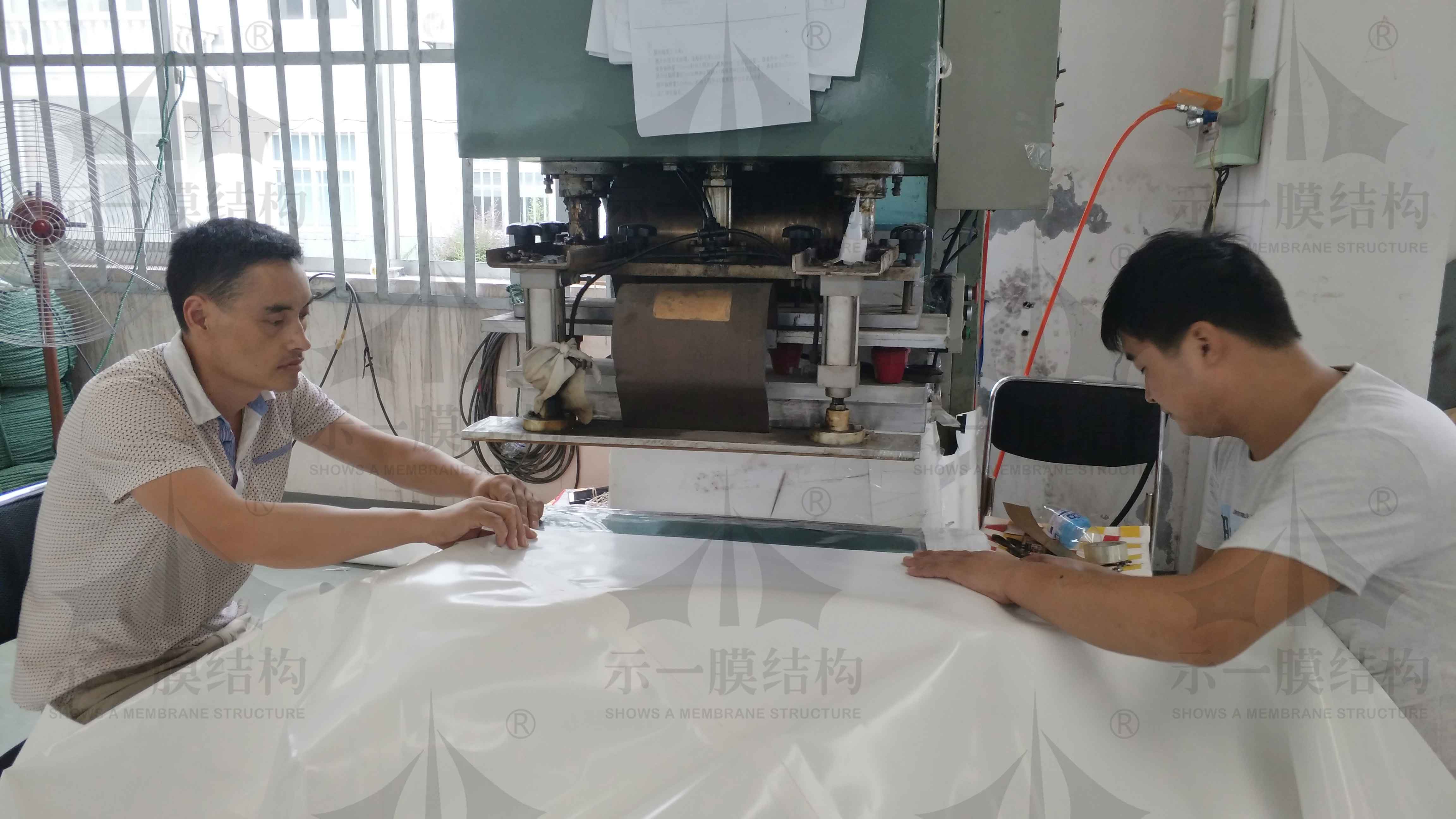

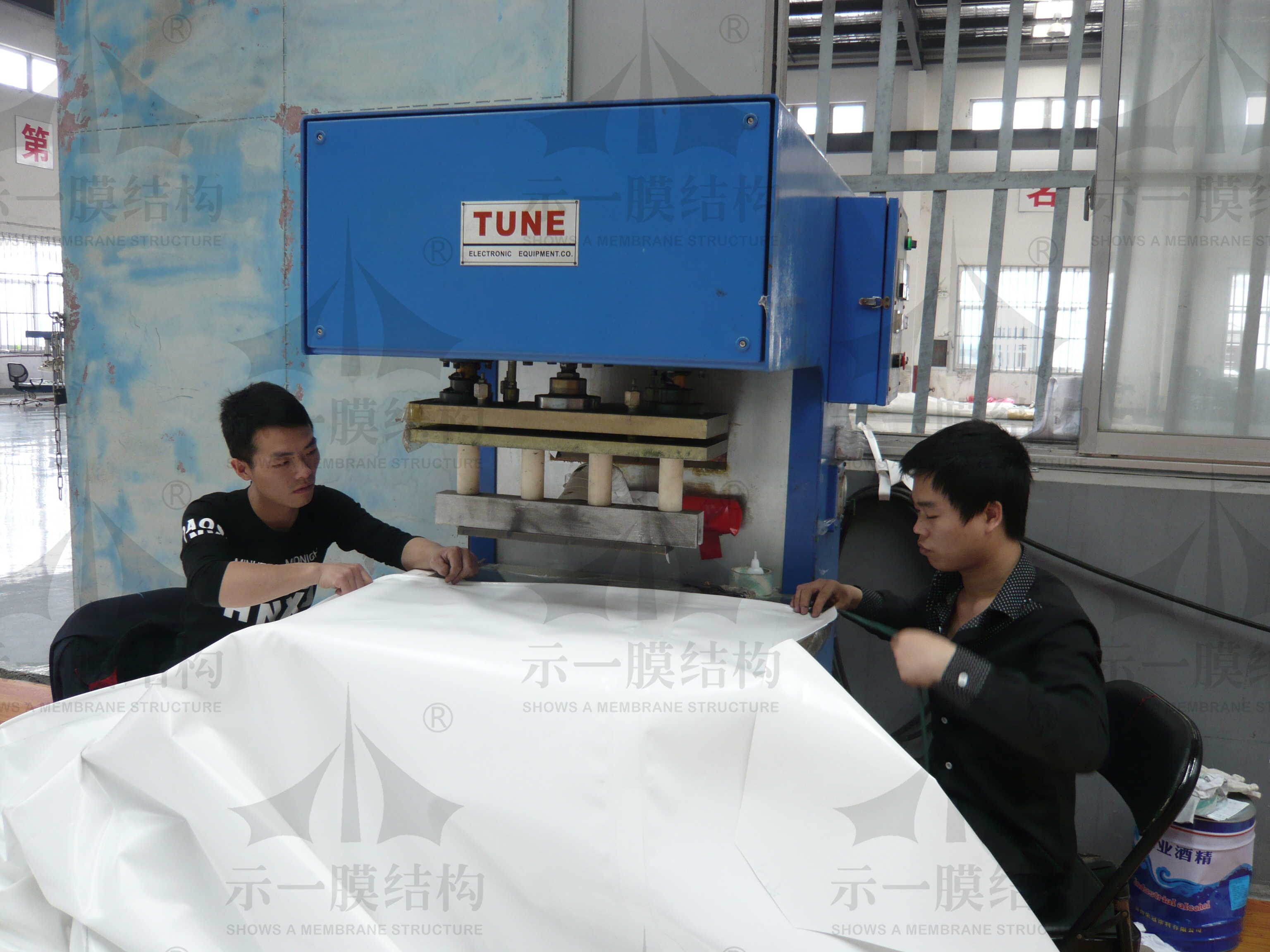

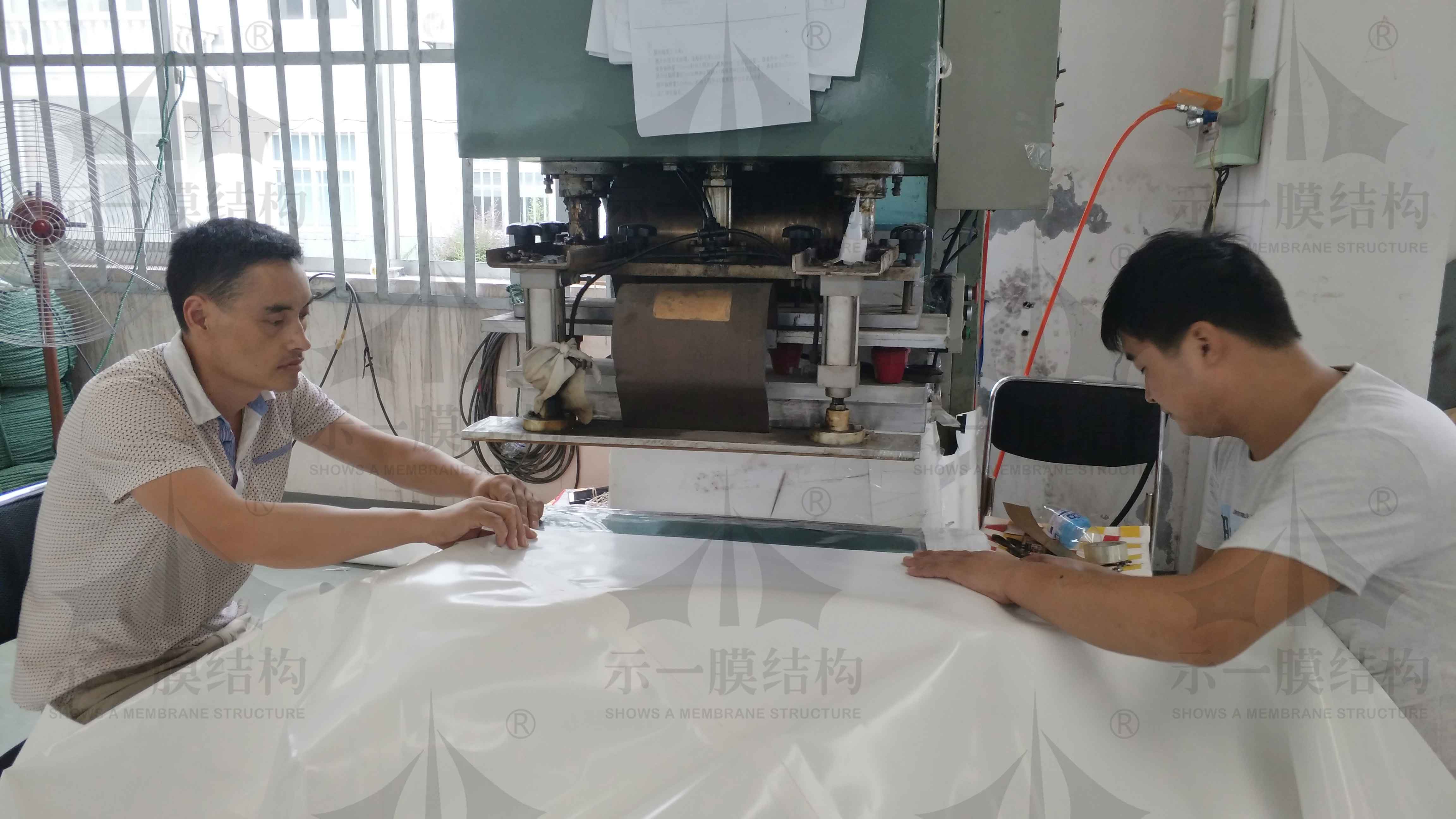

The second type, heat-sealing bonding:

Heat welding is to heat the bonding seam and melt the coating on the fabric, then apply pressure and cool the bonding seam. The film can be heated by blowing hot air on the film, or contacting the film with a heated object, or by using high frequency electromagnetic waves. Heat and bonding are used for PVC coated polyester filament fabrics and PTFE coated glass fiber fabrics. For PTFE-coated fiberglass fabrics, because PTFE cannot be melted by itself, a different material is required for the inner layer.

Third, mechanical bonding:

Although sewing and heat sealing have been widely used in film processing workshops, mechanical bonding is also sometimes used. There are three general forms of mechanical bonding:

1. Embed the rope at the edges of the two diaphragms, and clamp the splint at the overlapping position of the two diaphragms. Such splints are required to be discontinuous and movable.

2. Buried ropes at the edges of the two diaphragms, and embed the two buried ropes in the aluminum splint with two openings (like a dumbbell lying horizontally). The aluminum plywood is also discontinuous. This bonding method is less waterproof than the first.

3. The simplest method is to arrange many membranes in a row and fix them. This is the easiest and fastest way to install, but it is not waterproof.

Original finishing from Shanghai Shows A Membrane Structure Co., Ltd.

Reprint please specify